Special PCBs: Enhancing Performance in Harsh Environments

Printed Circuit Boards (PCBs) are

the backbone of electronic devices, but not all PCBs are created equal.

Specialized PCBs, designed to operate in harsh environments, play a crucial

role in enhancing performance, reliability, and longevity in demanding

applications. In this article, we explore the innovative applications of

special PCBs and their impact on various industries operating in challenging

conditions.

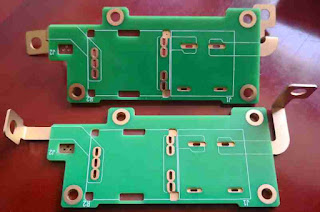

Understanding Special PCBs

Special PCBs are engineered to

withstand extreme temperatures, moisture, vibration, corrosion, and other

environmental stresses that standard PCBs may not tolerate. These PCBs are

designed using specialized materials, coatings, and construction techniques to

ensure optimal performance and reliability in harsh environments.

Innovative

Applications in Harsh Environments

- Aerospace and Defense: Special PCBs are extensively used in aerospace and

defense applications where they must withstand high altitudes, temperature

variations, shock, and vibration. These PCBs are crucial for avionics,

radar systems, communication equipment, and missile guidance systems.

- Automotive Electronics: In the automotive industry, special PCBs are deployed

in vehicles to withstand extreme temperatures, humidity, and mechanical

stress. They are used in engine control units (ECUs), ABS systems, airbag

sensors, and infotainment systems, ensuring reliable performance under

rugged conditions.

- Industrial Automation: Industrial environments pose challenges such as dust,

moisture, temperature fluctuations, and electromagnetic interference

(EMI). Special PCBs with robust designs and protective coatings are used

in industrial automation systems, PLCs (Programmable Logic Controllers),

motor controls, and sensors for reliable operation in harsh industrial

settings.

- Oil and Gas Exploration: Oil and gas exploration activities often take place in

harsh environments such as offshore rigs, deserts, and Arctic regions.

Special PCBs designed for high-temperature resistance, chemical

resistance, and reliability are employed in drilling equipment, control

systems, and data acquisition units.

- Medical Devices:

Medical devices used in hospitals, clinics, and harsh medical environments

require PCBs that can withstand sterilization processes, moisture, and

electromagnetic interference. Special PCBs are integral to medical imaging

systems, patient monitoring devices, and life support equipment.

- Renewable Energy:

In the renewable energy sector, special PCBs are utilized in solar

inverters, wind turbines, and energy storage systems. These PCBs must

endure outdoor conditions, temperature variations, and exposure to UV

radiation while maintaining electrical performance and reliability.

Key

Features of Special PCBs

- High-Temperature Resistance: Special PCBs use materials such as ceramic substrates,

high-temperature laminates, and metal-core PCBs to withstand elevated

temperatures without compromising performance.

- Corrosion Resistance:

Coatings and finishes like ENIG (Electroless Nickel Immersion Gold), HASL

(Hot Air Solder Leveling), and immersion silver provide corrosion

resistance, ensuring long-term reliability in corrosive environments.

- Vibration and Shock Tolerance: Special PCBs employ reinforced structures,

shock-absorbing materials, and secure mounting techniques to withstand

mechanical stress and vibration without component failure.

- EMI/RFI Shielding:

Shielding techniques such as conductive coatings, ground planes, and

shielding layers protect sensitive components from electromagnetic

interference (EMI) and radiofrequency interference (RFI), maintaining

signal integrity.

- Environmental Sealing: Sealing techniques such as conformal coating, potting,

and encapsulation protect PCBs from moisture, dust, chemicals, and

contaminants, enhancing durability in harsh environments.

Conclusion

The

innovative applications of special PCBs play a vital role in enhancing

performance, reliability, and safety in industries operating in harsh

environments. From aerospace and defense to automotive, industrial automation,

medical devices, renewable energy, and beyond, special PCBs enable electronic

systems to function seamlessly under extreme conditions. As technology advances

and demands for ruggedized electronics grow, the importance of specialized PCBs in optimizing performance and longevity in

harsh environments will continue to rise.

Comments

Post a Comment