Mastering PCB Design: Harnessing the Power of Via Knowledge

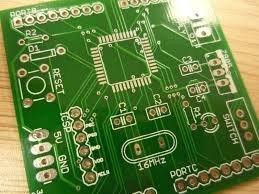

Printed Circuit Boards (PCBs) are the backbone of modern electronic devices, enabling compact, efficient, and reliable designs. Among the critical elements in PCB design, vias play a pivotal role in connecting different layers of a circuit board, ensuring seamless electrical pathways. Mastering the intricacies of via types, applications, and best practices is key to achieving superior PCB performance.

Understanding Vias in PCB Design

A via is a tiny hole drilled into a PCB to establish electrical connections between layers. Vias are filled with conductive material, such as copper, and are essential for multi-layer PCB designs. They enable vertical interconnections that are vital for compact and intricate circuitry. The three main types of vias are:

-

Through-Hole Vias: These pass through the entire PCB, connecting all layers. They are cost-effective and straightforward to manufacture, making them suitable for simple designs.

-

Blind Vias: These connect an outer layer to one or more inner layers but do not pass through the entire board. Blind vias optimize space, which is crucial for compact designs.

-

Buried Vias: Located entirely between inner layers, buried vias are invisible from the PCB's surface. They are commonly used in high-density designs where surface real estate is at a premium.

The Importance of Via Design Knowledge

Proper via implementation impacts critical PCB parameters, including signal integrity, thermal management, and mechanical durability. Mismanagement of vias can lead to performance degradation, increased noise, or even failure of the board.

Best Practices for Via Design

To harness the full potential of vias in PCB design, consider the following best practices:

-

Optimal Placement: Place vias strategically to minimize trace lengths and reduce electromagnetic interference (EMI). Use via fences or stitching vias in high-frequency designs to enhance signal integrity.

-

Size and Aspect Ratio: Choose appropriate via sizes and aspect ratios to balance electrical performance and manufacturability. Smaller vias save space but require advanced fabrication techniques.

-

Thermal Vias: Use thermal vias in power circuits or under heat-generating components to improve heat dissipation.

-

Avoiding Crosstalk: Maintain sufficient spacing between vias to prevent crosstalk, especially in high-speed designs.

-

Fill or Tent Vias: Filling vias with conductive or non-conductive material enhances structural integrity, while tenting vias with solder masks reduces contamination risks.

Tools and Techniques for Via Optimization

Modern PCB design tools, such as Altium Designer, Eagle, or KiCad, provide advanced features for via placement and optimization. Designers can simulate electrical and thermal performance to ensure their via design meets the required specifications. High-density interconnect (HDI) technologies, which rely heavily on blind and buried vias, are also increasingly popular for compact and complex PCB designs.

Advancing Your Skills in Via Design

As PCB designs become more sophisticated, staying updated on the latest via technologies and design methodologies is essential. Participating in workshops, leveraging online resources, and collaborating with experienced manufacturers can help designers refine their skills.

Conclusion

Mastering via knowledge is an indispensable part of PCB design. From enabling high-density interconnections to improving thermal management, vias hold the key to unlocking advanced PCB capabilities. By adhering to best practices and leveraging the right tools, designers can create efficient, reliable, and innovative PCBs that meet the demands of modern technology.

Comments

Post a Comment